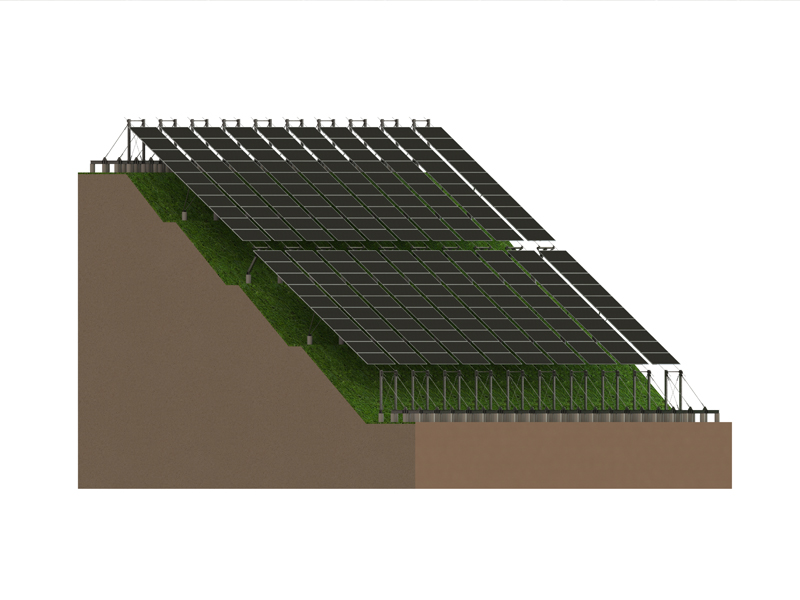

In recent years, with the development of the photovoltaic industry, land and roof resources have gradually decreased. Limited by the traditional support form, the undulating mountains, fish ponds with deep water levels, and sewage treatment plants with large spans cannot be fully utilized. The emergence of flexible bracket has solved the above problems, which is a new trend in the application of photovoltaic bracket.

Flexible Mounting Structure

Product Highlights

· Reduce land occupation resources: The span is large, and the span spacing of 10~60m can be installed.

· Increase the use of space: the height can be customized, and the height can be set to 2.5~16m.

· Reduce the amount of steel: Through the use of cable structure, the cost of ordinary brackets can be effectively saved by 10~15%

· Saving construction costs: The reduction in the number of pile foundations and the sliding characteristics of the cable structure can reduce the construction cost and period by 10-20%.

All-weather unobstructed: Overcome the ups and downs of the mountains and increase the power generation by about 10%.

Application:

Flat terrain such as fishing light, agricultural light, desert, grassland, parking lot, sewage treatment plant and undulating terrain such as sloping land.

Technical parameter

Foundation

Concrete/PHC Pile

Application

Flat terrain such as fishing light, agricultural light, desert, grassland, parking lot, sewage treatment plant and undulating terrain such as slope.

Wind load

0.58 kN/m²

Snow load

0.5 kN/m²

Design standard

Photovoltaic support structure design specification NB/T 10115,

Building structure load code GB 50009

National standards such as JGJ 257 technical regulations for cable structures

Material

Hot-dip galvanized carbon steel, high vanadium cable (anti-corrosion)

Warranty period

10 years warranty

Case photo

online service

online service +86 592-5211-388

+86 592-5211-388 info@esolarfirst.com

info@esolarfirst.com sales004_solarfirst

sales004_solarfirst sales12_solarfirst

sales12_solarfirst sales10_solarfirst

sales10_solarfirst +86 18959208686

+86 18959208686